How we work our handcrafted ceramics

The working process of our handcrafted ceramics consists of several stages. Each stage is essential to the success of the final product in this very long and delicate process. The Materia Ceramica workshop receives its products directly from the artisan factories in Deruta, where the clay artifacts are shaped, dried and undergo an initial firing (between 800 and 1000 degrees Celsius) and the subsequent cooling.

Glazing

La smaltatura è il metodo con cui l’oggetto di ceramica viene rivestito da smalto. Può essere eseguito usando un pennello, usando la pistola spruzzo o per immersione.

Una volta arrivato nel nostro laboratorio, l’oggetto in terracotta (biscotto) è pronto per essere pulito e smaltato.

Step 1: Clean the Piece

Cleaning the biscuit is essential before proceeding with glazing. Dust and moisture are in fact the main threats that could compromise the final result. Cleaning the piece can be done through the air jet of an air compressor or with sandpaper and a slightly moistened sponge.

Step 2: Prepare the Glaze

Lo smalto è formato da una miscela di polveri di silice, carbonato di sodio o potassio, di stagno e altri ossidi metallici mescolati ad acqua.

Nel nostro laboratorio prepariamo lo smalto in una capiente tinozza dove sciogliamo le polveri in acqua. Quindi lasciamo riposare il composto, per poi passarlo al setaccio molto fine almeno due volte, in modo da eliminare impurità e grumi. Mescoliamo e amalgamiamo lo smalto con un movimento rotatorio usando una pala di legno.

Step 3: Choose the Right Glaze Density

For perfect glazing, the right density of glaze must be chosen for each item: the larger the object, the lower the density of the glaze. The density can vary from 52 to 57 Bé°.

Step 4: Immersion Glazing

Nel laboratorio Materia Ceramica utilizziamo la tecnica di smaltatura ad immersione.

Usando le pinze immergiamo l’oggetto nello smalto con movimenti rapidi, assicurandoci di coprirlo in modo completo. Una volta estratto l’oggetto, lo smalto si asciuga rapidamente.

Step 5: Touch Up

Touch-up is the last step before proceeding with the decoration. Using a scraper and brush dipped in glaze, we delicately remove all the imperfections caused by the use of the clamps.

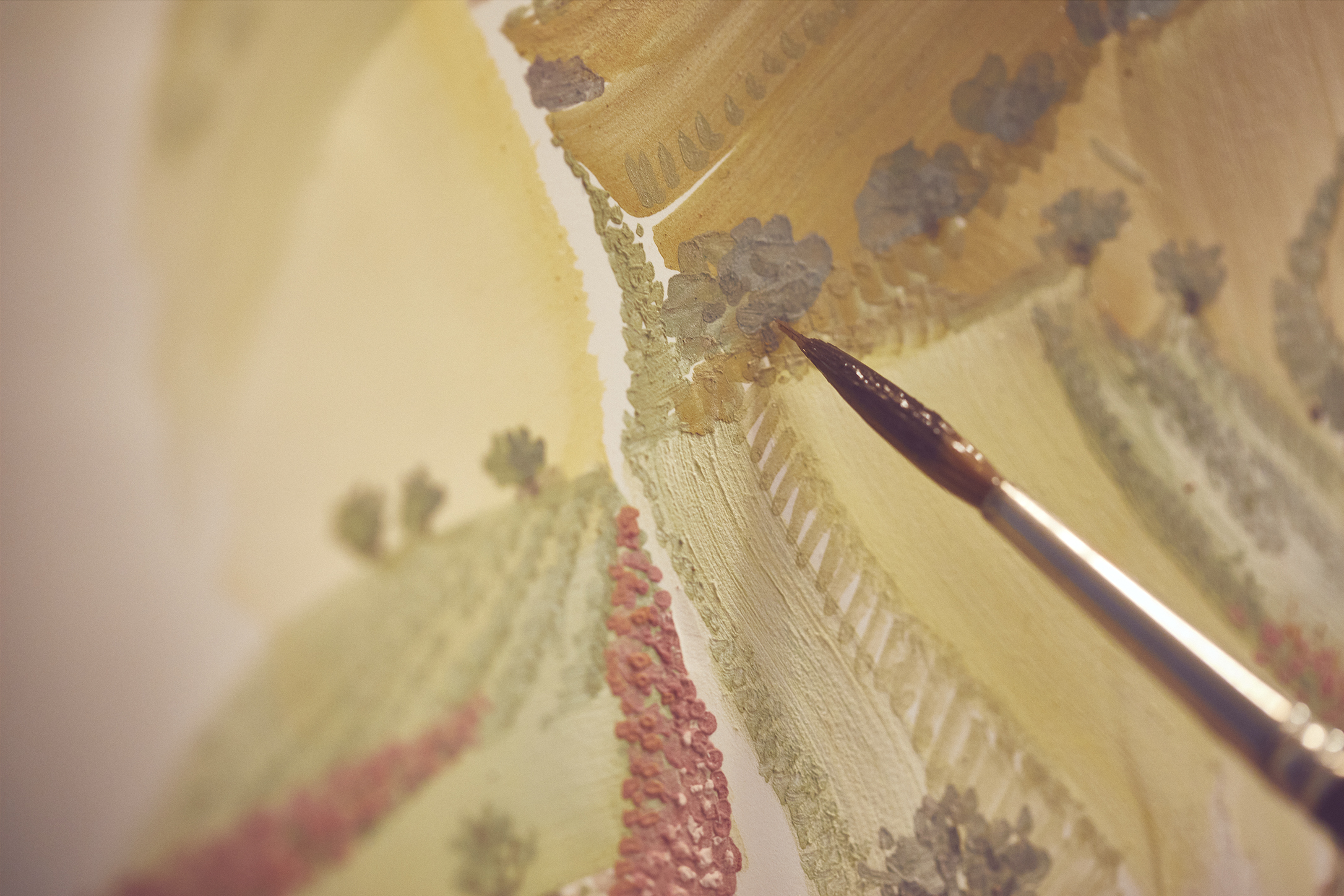

The Decoration

Once glazed, we can move on to decorating the piece.

It is at this stage in the working process of our handcrafted ceramics that each ceramic plate vase, or accessory takes on a life of its own.

Decorating techniques are varied and very personal.

Our products are decorated with freehand painting or with overglaze brushstrokes. In some cases we use the dusting technique to bring back the trace of the design to be painted.

Firing

Firing is the final stage in the working process of ceramic craftsmanship.

Firing the ceramic means implementing an irreversible but necessary process to obtain the hardness, resistance and majolica glazing – that is, vitrification of the glaze and decorations. It is therefore a fundamental step.

The firing schedule varies according to the size of the kiln and the number of objects being fired.

Generally, the firing stages are:

- – Slow progressive heating up to 500°C.

- – Progressive heating up to a temperature of 970°C.

- – Holding the maximum temperature for about 5 to 10 minutes in order for the internal temperature to reach a more uniform temperature.

- – Slow cooling down to 0°C.

The result of the long and delicate work in every phase is evident the moment the piece is removed from the kiln. Only at the end of this process can we admire the colors of our products and the decorations that make our handcrafted ceramics unique.